At Punchbowl, we understand that being a grower requires significant trust in the partnerships we form. Trust is what brings out the best in our customer relationships, and it has been the driving factor behind our innovative solutions. In 1988, our then small kiwifruit orchard and packhouse was struggling to find a reliable supply of quality packaging and automation. In response to this, Rob Craig (founder), used his Kiwi ingenuity to create solutions specific to the Kiwifruit industry. We set up our own customer-centric packaging and automation company, focused on developing practical solutions to satisfy our customers’ unique needs, with packaging and automation solutions that have grown to cover a range of industries. Today we have advanced our own packhouse and developed our automation manufacturing capability to provide our customers with the best solutions.

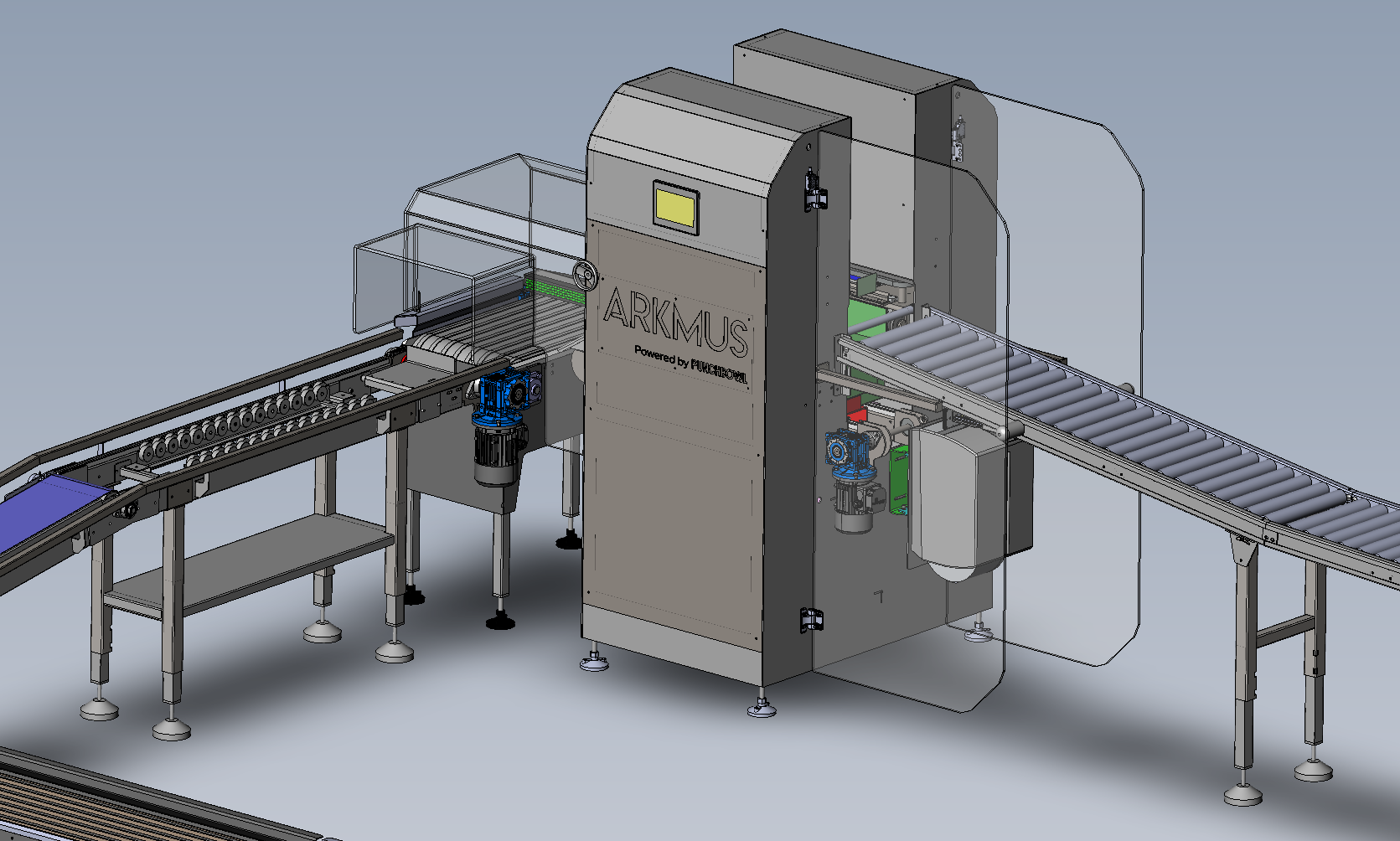

Automation Machinery

Bringing world-leading automation technology to New Zealand. Off the shelf equipment with Plug and Play automation machines which can addon to existing equipment. Available for a quick and easy solution, offering improved efficiencies, ROI and productivity benefits.

Custom Automation

We can streamline key areas of your packing process with custom-designed automation solutions. Our dedicated design and engineering team create bespoke industry solutions to solve your packing problems and increase productivity. Have a big project that needs tackling? Get in touch.

PRIMARY PACKING

Punchbowl Automation can help with solutions for packing your finished product into its primary packing. Either via our supply partners or from equipment solutions we manufacture ourselves.

ERECTING AND DE-NESTING

From erecting RSC’s to Trays or simply de-nesting Punnets. Whatever your packaging supply requirements are, our team of engineers would love to help find or build your solution.

SECONDARY PACKING

Packing inners such as Punnets into outers such as Trays or Crates, is a core capability. Our PunnetMate solution for example is helping to significantly reduce labour costs for our customers. Ask us if we have a solution for you!

CONVEYING & ELEVATING

Through our partners Intralox and Flexlink, we are able to manufacture conveying, elevating and sorting conveyor solutions to move your product to where it needs to go. We are experts in packaging and product flow.

BAG LINING & CLOSING

Through our partners Niverplast and our own machinery brand ARKMUS, we have your bag and liner placing, cuffing, decuffing and closing requirements covered. We are proud to be true leaders in this space and have over 120 machines installed.

LABELLING

Outers need labelling? We offer online print and apply labelling solutions, either stand alone or integrated within our machinery solutions.

STACKING & PALLETISING

If your outers need stacking or palletising, then we want to know about it. We can offer solutions to prepare your products for distribution.

AFTERCARE & GENERAL ENGINEERING

Punchbowl Automation has several workshops and service technicians around the country ready to support your equipment. Whether you need regular or breakdown servicing, or guards or fences constructed, we’re here to help.

Hear from our customers

"Knowing who to trust in business seemed like a real key thing, we have worked with Punchbowl for a number of years now. We have saved between 15-20 staff on the floor. We have benefited from consistent production that is easy to work with.”

Paul Gardiner, Whitehall Fruitpackers

"Proven over multiple seasons, the Speediplasts have delivered consistently high speeds and low fail rates. Each machine replaces the roles of five people and the accurate, repeatable placement of each bag means we see significant benefits in downstream activities. This is a critical pathway for further automation. Punchbowl’s aftersales service support has been excellent. Bags supplied have also been of a high standard and supply has been excellent.”

Phil Karl, General Manager Operations, Eastpack